PDR X-Ray Inspection Systems

High Resolution Image Clarity – Affordable Pricing

PDR X-ray Solutions 2D and 2D+ X-ray systems have set a new industry standard for high quality X-ray images at an affordable price. Choosing the correct system for your requirements such as X-ray for quality control or X-ray for process control is vital for the success of both X-ray PCB inspection programs as well as X-ray semiconductor inspection programs, Component Counterfeit Detection, and X-ray Failure Analysis

PDR’s 90kV X-ray and 130kV X-ray systems are engineered with high-quality materials and craftsmanship and X-ray safety standards exceeding the most stringent requirements for industrial safety. All X-ray non-destructive inspection systems built by PDR are equipped with a suite of X-ray image processing tools and features that incorporate cutting-edge technologies to insure that your X-ray system delivers quality X-ray images and the power of analytic tools required for a successful X-ray program.

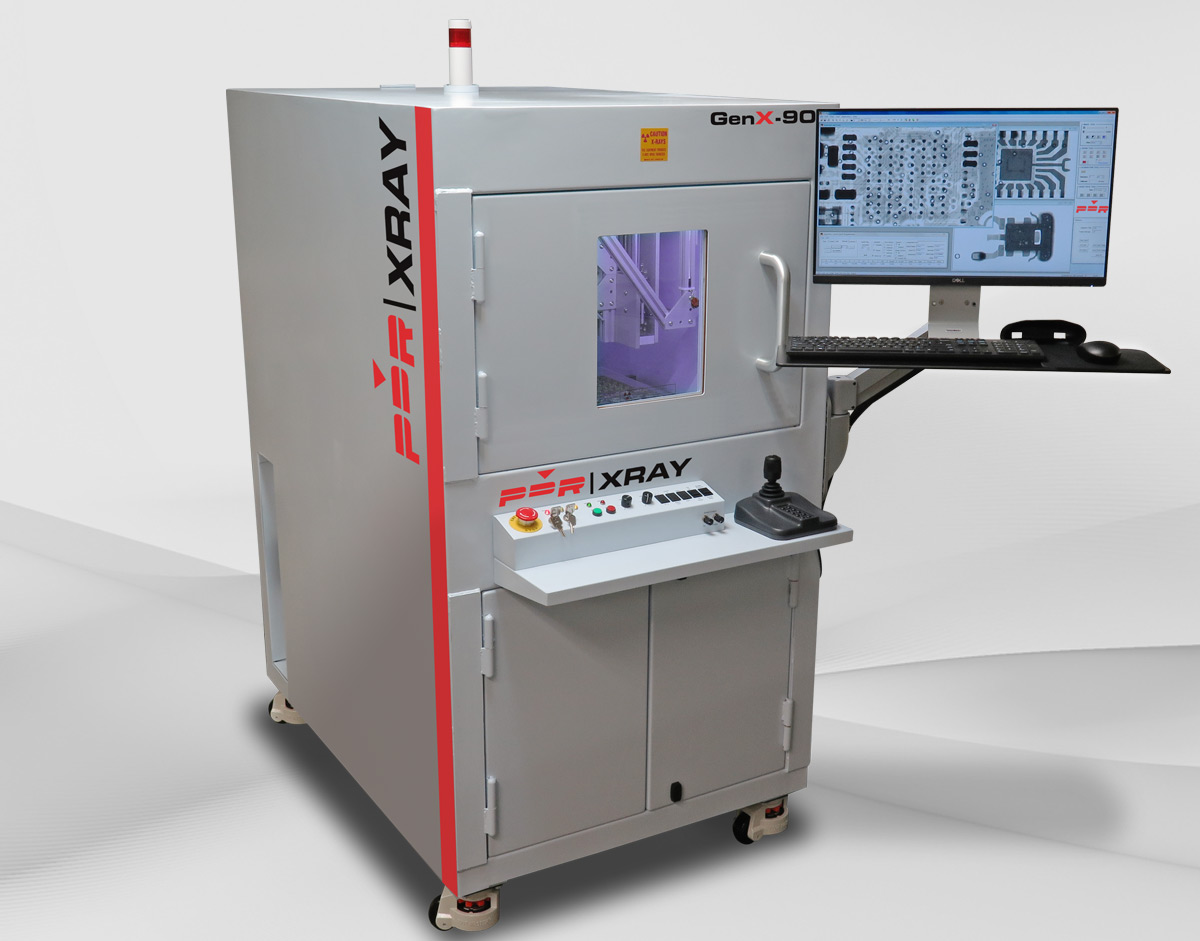

GenX-90P

Ultra High-Performance, 90kV, Compact X-Ray System

High Quality NDT X-Ray Imaging Solutions for PCB Analysis, Medical Device Inspection, Porosity Analysis and Custom Applications.

Designed Specifically for Quality Control, Production Process Validation, Research and Development, and MRO applications.

Detect a wide range of manufacturing/process defects including BGA, QFN and IGBT attachment, PTH filling, interfacial voiding, die attach, component cracking, mis-alignment, and bridging with automated inspection routines resulting in Pass/Fail Analysis.

- BGA Inspection/Analysis

- Counterfeit Inspection

- Porosity/Voiding Detection

- Medical Device Inspection

- Wire Bond Inspection

- LED Inspection

Main features include:

- Truly Remarkable Image Clarity with proprietary HD Camera and Software

- Compact System, PCB sizes up to 21”(533mm) X 17.5” (445mm)

- Customizable Flat Panel Detectors or Image Intensifier options to meet your application requirements

- 90kV, 8 Watt, 4um X-Ray tube, 0.18mA with Magnification up to 1100X

- Programmable 4 Axis ( X,Y, Z1/Z2) fully motorized Motion Control

- BGA/QFN/Flip Chip Software Pass/Fail – Sphere Size - Void * 3D Gray Scale Option

- Wide Range of Analysis and Enhancement Tools Powered by PXI Technology

- Frame Averaging, Quad View Analysis, Image Filters, Reporting, More…

- Tilt/Rotate Oblique View and LED Targeting System Options

- Flexible and EASY-To-OPERATE system controls and Software

- Easily Upgrades to 130kV X-Ray as your needs change

- Engineered for Low Maintenance and Trouble Free Operation

- Quality Built Made in the U.S.A. Supported Worldwide

PDR GenX-130P

High Powered Performance, 130kV, Compact X-Ray System

High Quality NDT X-Ray Imaging Solutions for PCB Analysis, Medical Device Inspection, Porosity Analysis and Custom Applications.

Designed Specifically for Quality Control, Production Process Validation, Research and Development, and MRO applications.

Detect a wide range of manufacturing/process defects including BGA, QFN and IGBT attachment, PTH filling, interfacial voiding, die attach, component cracking, mis-alignment, and bridging with automated inspection routines resulting in Pass/Fail Analysis.

- BGA Inspection/Analysis

- Counterfeit Inspection

- Porosity/Voiding Detection

- Medical Device Inspection

- Wire Bond Inspection

- LED Inspection

Main features include:

- Truly Remarkable Image Clarity with proprietary HD Camera and Software

- Compact System, PCB sizes up to 21”(533mm) X 17.5” (445mm)

- Customizable Flat Panel Detectors or Image Intensifier options to meet your application requirements

- 130kV, 16W, 5um to 6um X-Ray tube, 0.18mA with Magnification up to 665X

- Programmable 4 Axis ( X,Y, Z1/Z2) fully motorized Motion Control

- BGA/QFN/Flip Chip Software Pass/Fail – Sphere Size - Void * 3D Gray Scale Option

- Wide Range of Analysis and Enhancement Tools Powered by PXI Technology

- Frame Averaging, Quad View Analysis, Image Filters, Reporting, More…

- Tilt/Rotate Oblique View and LED Targeting System Options

- Flexible and EASY-To-OPERATE system controls and Software

- Engineered for Low Maintenance and Trouble Free Operation

- Quality Built Made in the U.S.A. Supported Worldwide